Conventional Lube Oil Mist Technology and Full Standby Protection: A Comprehensive Overview for Engineers and Maintenance Professionals

In the realm of industrial machinery and equipment, lubrication plays a critical role in ensuring smooth operation, minimizing wear and tear, and extending component life. Among the various lubrication methods, conventional lube oil mist technology and full standby protection have gained widespread recognition for their effectiveness and reliability. This article delves into the intricacies of these technologies, exploring their principles of operation, advantages, applications, and best practices for implementation.

5 out of 5

| Language | : | English |

| File size | : | 12011 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 233 pages |

Conventional Lube Oil Mist Technology

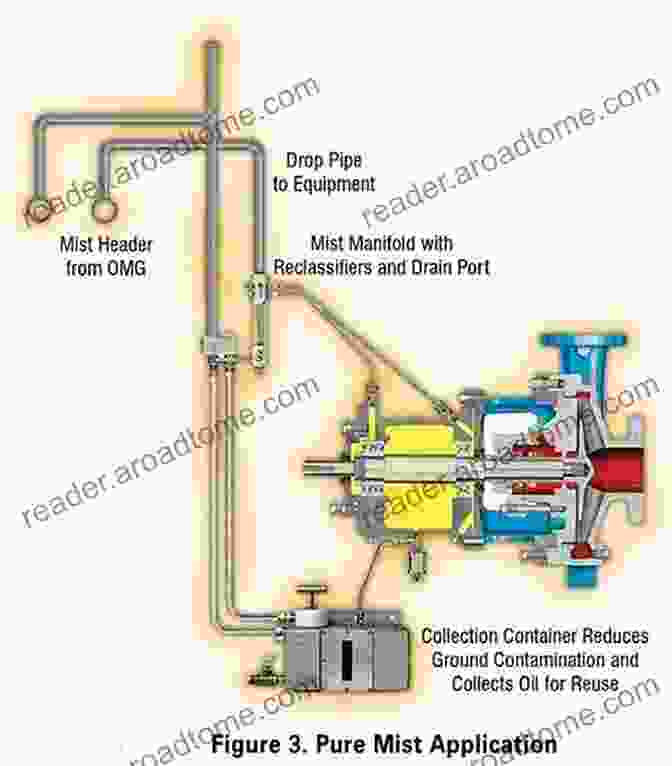

Conventional lube oil mist technology involves atomizing a high-quality lubricating oil into a fine mist that is then dispersed throughout the lubrication zone. This mist effectively coats all moving surfaces, providing a continuous layer of lubrication that reduces friction, wear, and heat generation. The mist is typically generated by a dedicated mist generator or lubricator that operates on compressed air.

Principles of Operation

The process of generating lube oil mist involves several key components:

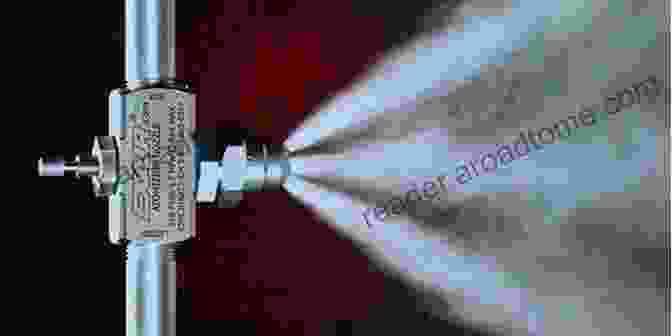

The mist generator operates by forcing compressed air through a nozzle, creating a high-velocity airstream. This airstream draws lubricating oil from a reservoir and atomizes it into a fine mist. The mist is then carried by the compressed air through a network of distribution lines to the lubrication points.

Advantages of Conventional Lube Oil Mist Technology

Conventional lube oil mist technology offers several notable advantages over traditional lubrication methods:

Applications of Conventional Lube Oil Mist Technology

Conventional lube oil mist technology finds widespread application in a variety of industrial settings, including:

Full Standby Protection

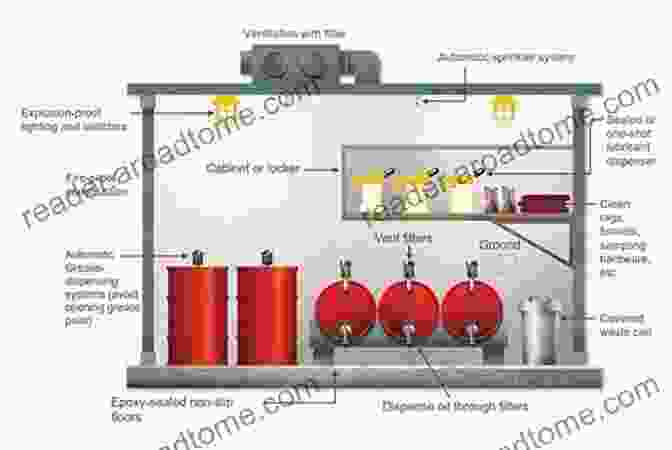

Full standby protection is a complementary technology to conventional lube oil mist lubrication that provides comprehensive protection for critical machinery during periods of shutdown or standby operation. This technology involves injecting a protective fluid or gas into the lubrication zone to prevent corrosion and wear during extended idle periods.

Principles of Operation

Full standby protection systems typically consist of the following components:

During shutdown or standby operation, the control system triggers the injection system, releasing a predetermined amount of standby fluid or gas into the lubrication zone. This protective layer prevents moisture and contaminants from contacting metal surfaces, reducing the risk of corrosion and wear.

Advantages of Full Standby Protection

Full standby protection offers several key advantages:

Applications of Full Standby Protection

Full standby protection is particularly beneficial for critical machinery in industries such as:

Conventional lube oil mist technology and full standby protection are indispensable technologies for industrial maintenance and reliability professionals. By providing continuous lubrication and comprehensive protection during periods of operation and shutdown, respectively, these technologies help extend equipment life, reduce maintenance costs, and improve overall operational efficiency. Engineers and maintenance professionals should carefully consider the principles of operation, advantages, and applications of these technologies to optimize the reliability and performance of their industrial machinery and equipment.

Image Alt Attributes

5 out of 5

| Language | : | English |

| File size | : | 12011 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 233 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Jamie BellFollow ·4.7k

Jamie BellFollow ·4.7k Jack PowellFollow ·6.6k

Jack PowellFollow ·6.6k John KeatsFollow ·6.4k

John KeatsFollow ·6.4k Cody RussellFollow ·3.2k

Cody RussellFollow ·3.2k Yasushi InoueFollow ·7.2k

Yasushi InoueFollow ·7.2k Jonathan FranzenFollow ·12.2k

Jonathan FranzenFollow ·12.2k Jack LondonFollow ·10.5k

Jack LondonFollow ·10.5k Foster HayesFollow ·2.8k

Foster HayesFollow ·2.8k

Brady Mitchell

Brady MitchellUnveiling the Apprehended Vital Truth for the Bride of...

In the tapestry of life, where trials and...

Eric Nelson

Eric NelsonDivine Energy Harmony Way: Embracing the Power Within for...

In the realm of personal...

Robert Louis Stevenson

Robert Louis StevensonUnlock the Secrets of Calf Growth and Development: A...

Are you an aspiring...

Gerald Parker

Gerald ParkerPhysician Life In The Shadow Of Polio: A Harrowing and...

A Riveting Tale of Determination Amidst a...

5 out of 5

| Language | : | English |

| File size | : | 12011 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 233 pages |