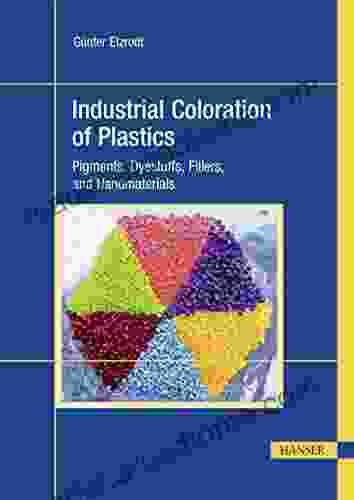

Plastic has become an indispensable part of our modern world, from the packaging we use to the cars we drive. And while we often think of plastic as being white or colorless, the truth is that it can be colored in a wide variety of ways.

Industrial coloration of plastics is a complex and fascinating process that involves the use of pigments, dyes, and masterbatches. In this article, we will explore the different methods of plastic coloration and discuss the latest techniques and applications in this field.

Pigments vs. Dyes

The two main types of colorants used in plastic coloration are pigments and dyes. Pigments are insoluble particles that are dispersed throughout the plastic, while dyes are soluble and are absorbed into the plastic.

Pigments are typically more stable than dyes and are less likely to fade over time. They are also more resistant to heat and chemicals. However, pigments can be more difficult to disperse evenly throughout the plastic, which can result in color variations.

Dyes, on the other hand, are easier to disperse and can produce more vibrant colors. However, they are less stable than pigments and can fade over time. Dyes are also more susceptible to heat and chemicals.

Masterbatches

Masterbatches are a type of color concentrate that is used to color plastics. Masterbatches are typically made from a combination of pigments, dyes, and polymers. They are available in a wide variety of colors and can be used to color plastics in a variety of ways.

Masterbatches are often used to color plastics that are difficult to color with pigments or dyes. They can also be used to achieve specific color effects, such as metallic or pearlescent finishes.

Color Matching

One of the most important aspects of plastic coloration is color matching. Color matching is the process of creating a plastic that matches a specific color standard. This can be a challenging task, as there are many factors that can affect the color of a plastic, such as the type of resin, the colorants used, and the processing conditions.

There are a number of different methods that can be used to color match plastics. The most common method is to use a spectrophotometer to measure the color of a plastic and then adjust the colorants until the desired color is achieved.

Applications of Industrial Coloration of Plastics

Industrial coloration of plastics has a wide variety of applications in a number of different industries. Some of the most common applications include:

- Packaging

- Automotive

- Appliances

- Toys

- Medical devices

The use of color in plastics can serve a number of purposes, such as:

- Identification

- Branding

- Aesthetics

- Function

For example, the color of a plastic packaging can be used to identify the product inside. The color of a car can be used to brand the vehicle and make it stand out from the competition. The color of a toy can be used to make it more appealing to children. And the color of a medical device can be used to indicate its function.

Industrial coloration of plastics is a complex and fascinating process that has a wide variety of applications in a number of different industries. By understanding the different methods of plastic coloration, you can create plastics that are both beautiful and functional.